Product Series

What We Support

By gaining a lot of experience in variety of field in cable assembly, connectors and antenna generate unique design and manufacturing ability.

We focus on the proportion of electronic products such as the series of video convertor peripherals, USB Type-C devices. With continuous innovation and R&D capabilities as our core value , Wieson fights into iOT- smart home application.

Vertically integrated business making Wieson is able to provide fast and professional total solutions to our customers.

We are the best partner of you.

OEM

►Open Tooling

►Manufacturing Execution System

►Manufacture Service

►Reliability test

JDM

►ID Co-Develop

►Mechanical Design

►Tooling build

►PCBA Design

►Completed test implement

ODM

►Self-developed products for customer labeling

►Customized Products

R&D Capability

| EE Capability | ME Capability | |

|---|---|---|

| Design | Solution survey Schematic design PCB design |

Electronic Mechanical Product Design Product assembly Design (2D, 3D) |

| Analysis | Signal Integrity / Circuit Impedance analysis |

ANSYS--Mechanical / Structure Moldex 3D--Tooling Design / Injection |

| Validation | Electrical Lab. (internal lab and outsourcing lab) Environment Lab. (internal lab and outsourcing lab) |

Mechanical Lab. (internal lab and outsourcing lab) Environment Lab. (internal lab and outsourcing lab) |

| Technical Support | Patent / Safety / Association certification (Patent Search、UL、CE、FCC、VCCI….Service) |

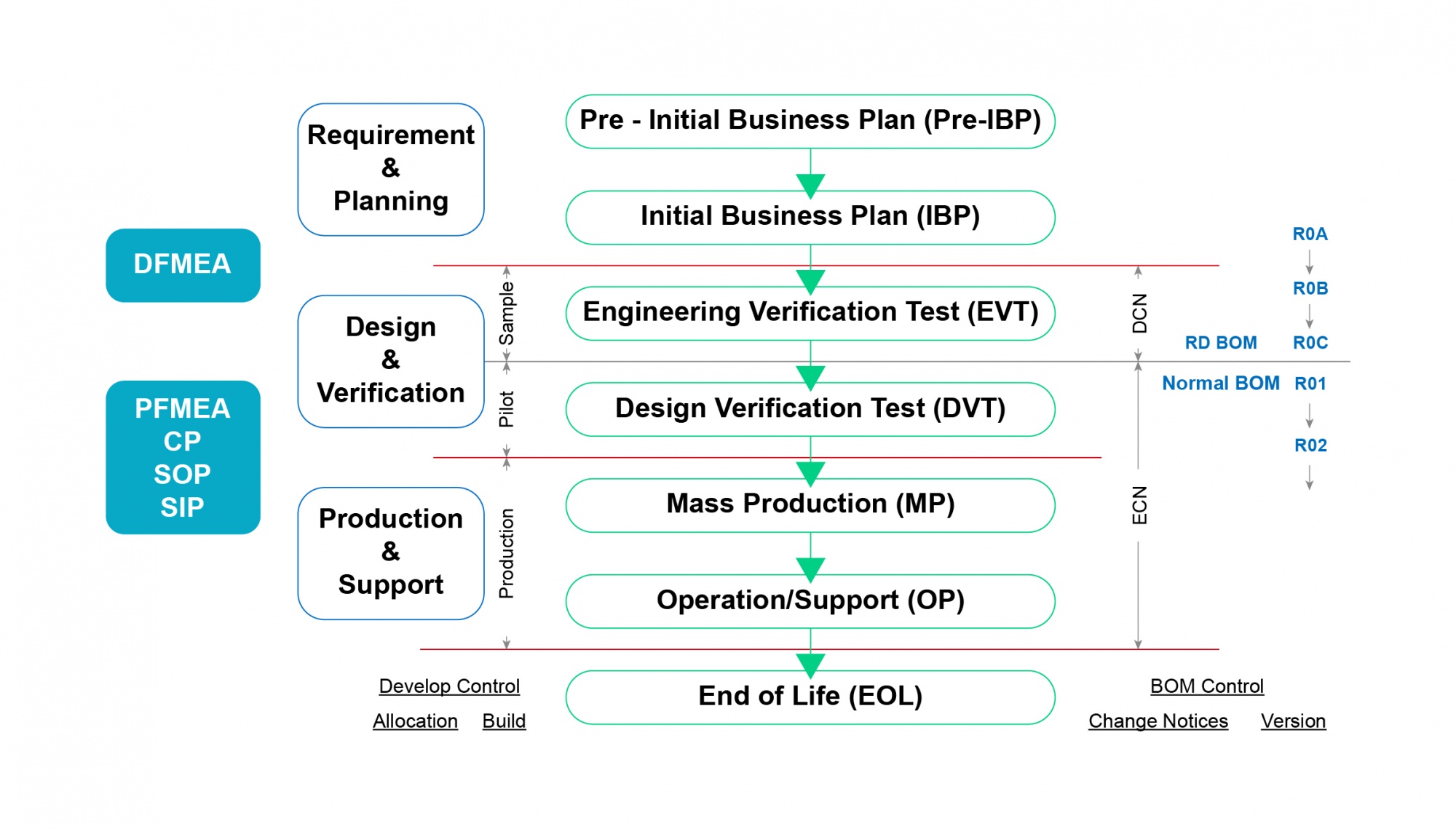

Development Process

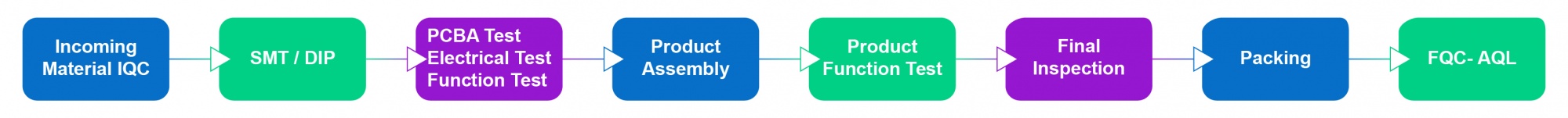

Mass Production

Plastic Injection Product Capabilities

Germany GOM ATOS 3D Scanner Technology

GOM ATOS 3D scanner are able to convert the complex surface into CAD drawing in 30 mins. Molds parts like sliders, electrodes dimensions can be 100% verify before assembly. Trial Injection parts not only points but surface can be measured and found the problem in early stage.

| Model | GOMA ATOS Core |

|---|---|

| Tolerance | +/- 0.01mm |

| Process time | 30mins-60mins |

| Applied object | electrodes, tools core/ cavity, sliders, complex injected parts |

Tools average trail time 3.5 -> 2.8

FAI accuracy increase 10%

Internet of Machine by APP

More than 150 machines connected to internet includes all the injection, CNC, EDM and wire-cut machines.

Real-time production status can be monitored by smart phone app. Multi-data are controlled and recorded into datebase avoid manual mistake.

Automatic alter message sent to Wechat get attention from all level of management.

Production utilization increase 15% up

Night shift efficiency increase 30% up

No hidden data

EROWA

Tool making process Control system

Erowa MoldLine control links the CAM programming, CNC machines, measure, EDM together by internet and RIFD chip on electrodes jigs.

No manual implement data to CNC/EDM machines, the manufactory mistake take in action as early as the part been made.

Reduce shopfloor technician, no manual mistake, increases accuracy.

.jpg)

_

Advance Automation bulid-up

Advance Automation

Insert metal molding + auto packing

• Required high quality tooling

• Mature automation equipment

• Two advance auto system in production, Three more in May

Cutting Jig

Cutting jig for gates implemented over 30% of production tools

Automatic film assembly

Machine replace hand assembly

one by one

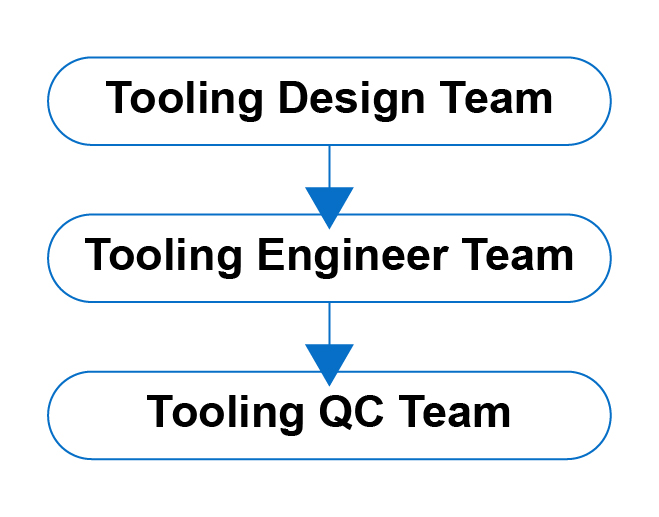

Tooling Factory

Tooling Design Engineer: 20

Moldflow Engineer: 1

CAD/CAM:

AutoDesk CAD, Pro-E5.0, UG9.0, Moldfolw

Tooling Engineer: 6

Experienced tooling engineers that in charged to monitor tooling status. Reviewing with customer RD

Measurement Engineer: 4

Control the precision of tooling and FAI dimension ensure the tooling quality, include a 3D CMM,3D scanner

Molding Factory

Electric Injection Molding Machines: 67 units

Primarily Japanese-made, featuring high precision, high production efficiency, and energy-saving performance.

Two-Color Injection Molding Machines: 17 units

Tonnage ranges from 180T to 380T, with a complete range of sizes to meet diverse product requirements.

Hybrid (Hydraulic-Electric) Injection Molding Machines: 21 units

Tonnage ranges from 50T to 1000T, available in a full range of sizes.

T-Mold Injection Molding Machines: 4 units

Vertical Injection Molding Machine: 1 unit

Vertical Injection Molding Machines: 17 units

Machine tonnage ranges from 50T to 85T, featuring high precision and high production efficiency. Equipped with automatic CCD inspection systems, enabling fully automated production.

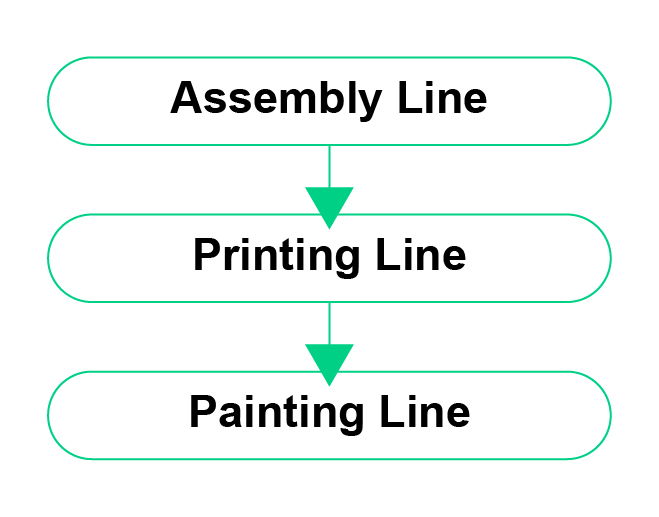

Post Processing Factory

Assembly line: 18

High flexibility with total 18 assembly line with a hundred of people.

Provides all kinds of prints.

Auto spindle line: 3 lines

Robot/semi-auto/manual

Painting line: 6 lines

Auto-install nuts machine: 8

Diversify painting lines provide sufficient capacity.

Auto-install nuts machine provides great capacity and stability.

Production capacity

Tooling capacity

.Average annual 400 tooling

. Max 60 tooling a month

. High-end Japan precise machineries

. Engineers, 25. Technicians 50

Moldling capacity

. Total 110 injection machines

. Size 50T-1000T include 2k injection

. Under 300T all Japan precise electric injection machines

. 50T-150T injection machines -> 65

.Automation all equipment 5 axis robot able to insert molding without operation involved

Equipment

. CNC/EDM/Wire-cut 21 set

. Injection Machines 66 set

Download Drowing

Please enter your E-mail to download drowing, thanks!